Sub micrometer, automous Vibration Logger

It has been our experience that end-users of high-precision equipment have seldom quantitative estimates of the actual vibration levels in their working environment. The two most cited reasons for this are the lack of unexpensive, practical vibration recording and analysing system, so that they must rely on external companies. This places severe limitations on the number and duration of possible vibration recording. Alas, vibrations are both space-wise and time-wise dependent. And their harshness is also very much case-dependent, so that measurement campaigns often results in an information deluge, but without clear cut conclusion.

As it appears, understanding a vibration-related problem is often an iterative process, which is best achieved in the field, by trial-and-error. It is also essential to have “early warning” when additionnal vibration sources are introduced. This saves the pain of having to identify vibration inducing components a posteriori, among dozens of candidates which can not always be shut off on-demand.

Our portable vibration logger is an answer to that problem. It will autonomously and continuously record vibration signals, analyse, and store statistics in terms of 1/3 octave values, directly comparable to ISO VC or NIST-A curves. This is useful before implementing a new instrument, but also serves to guarantee that a “quiet” environment will remain so over the years.

Accurate, drift-free time stamping is also granted, so that it is possible to distinguish between background noise and unique events.

Data will be permanently stored on the device using micro SD card, but can also be interrogated remotedly over Wi-Fi.

Sub-micrometer resolution is guaranteed, along with bandwith typical of mechanical vibration problems [1-80Hz].

It can powered with either LiPo battery or a USB power bank.

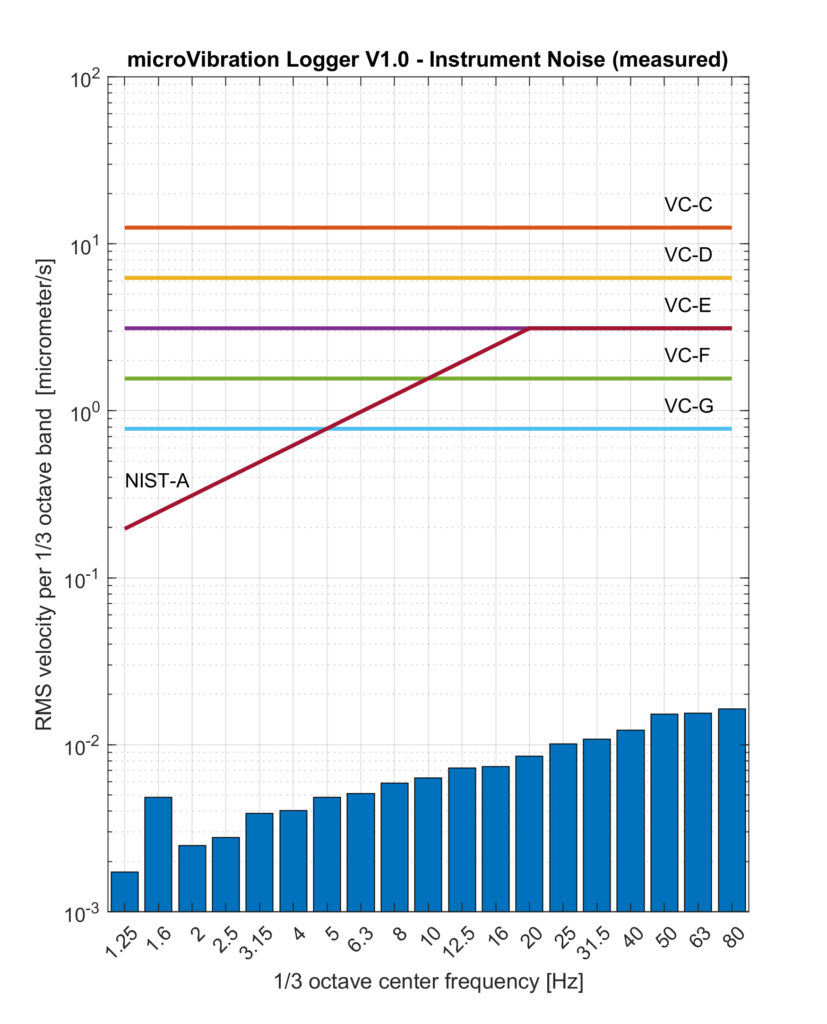

Our Version 1.0 is available since November 1st, 2020, as a single or dual channel version. Product finalization is ongoing, but performance is clearly there: associated with a 100V/m/s geophone, the instrument background noise is about 2 orders of magnitude lower the most stringent environmental requirement (VC-G, equivalent to NIST-A1).

The logger uses a series of real-time digital filters, in order to estimate both displacement and velocity results.

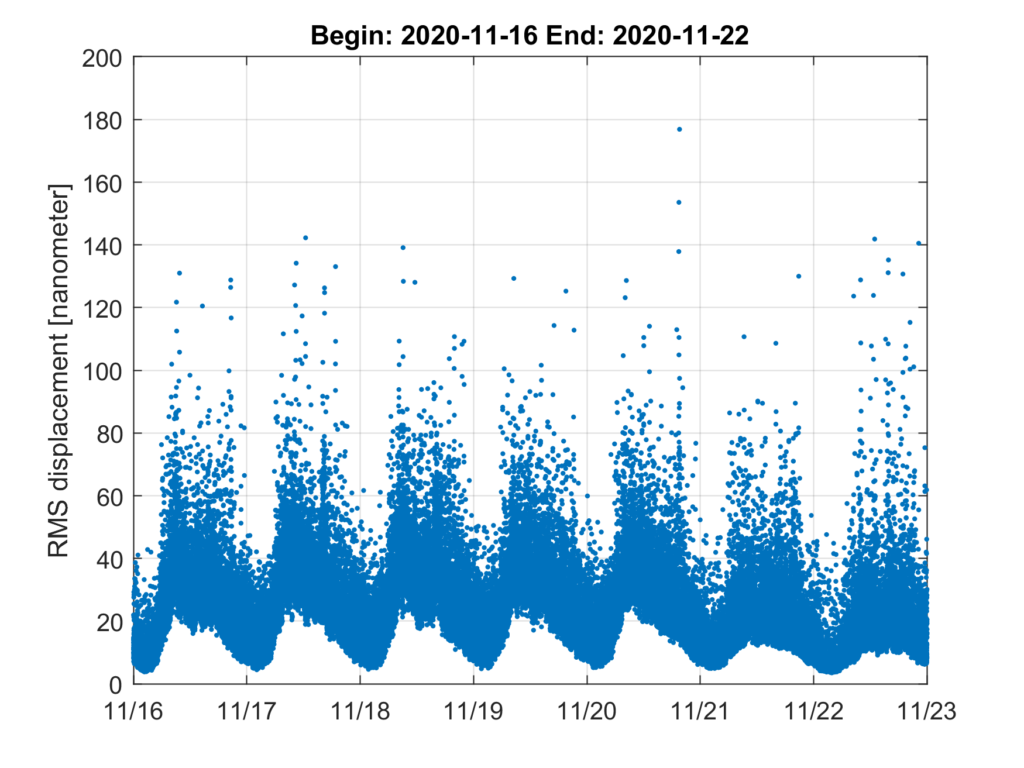

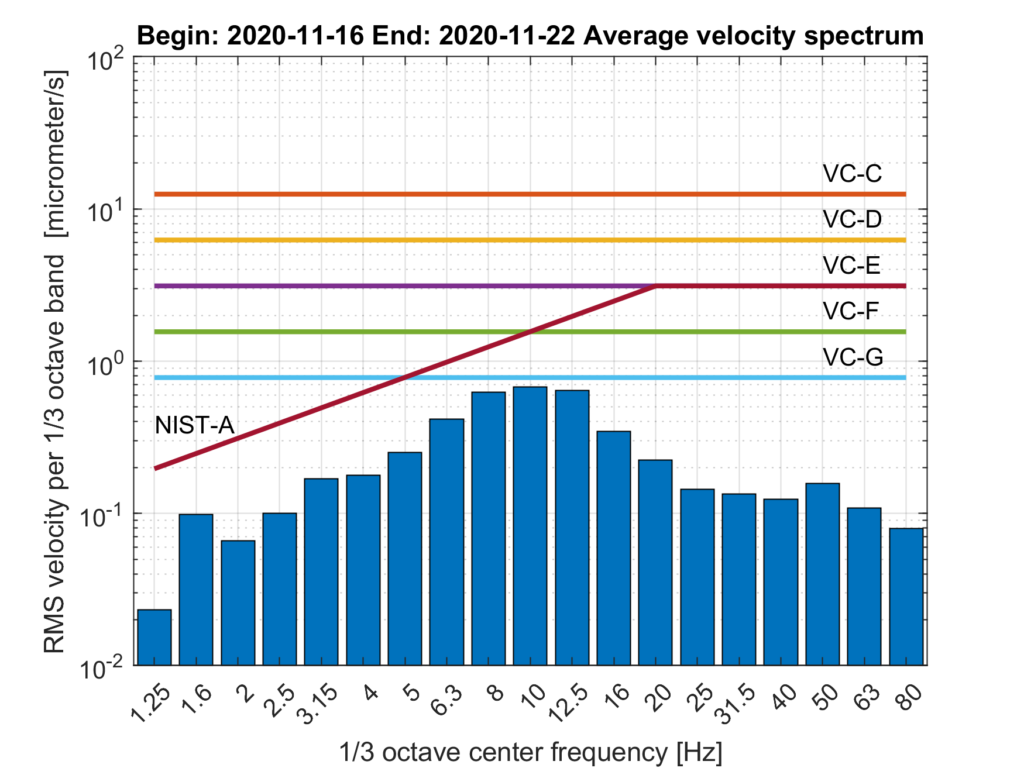

As an illustration, above is the RMS displacement in the [1-80Hz] bandwidth as measured in our lab, over a typical week (Monday to Sunday). During nightime, the RMS displacement reads about 6nanometers (to be compared with the instrumental noise of about 1nanometer). High-intensity events are caused by construction work located 100m away.

Overall, the VC-G curve is attained. This result is typical of urban areas, when no amplification by the civil works exists (our lab is located in a underground basement with masonry walls. The sensor was located on concrete slab, close to a supporting wall, and there was no active equipment). The highest velocity levels are attained around 10Hz, which is caused by nearby road traffic. Attaining lower vibration levels (VC-H and below) would certainly require special effort and possibly active control countermeasures.

To learn more about microVibration logger or request a free trial, use the contact form.